INTELLIGENT MILKRUN: INDUSTRY 4.0 MADE IN EDiM LANDS IN THE USA

Milkrun, the project created to innovatively automate the feeding process of the holding furnaces of the die-casting machines in the foundry department of EDiM was presented at the NADCA Congress held on 1 October 2019 in Cleveland, Ohio

The Milkrun project, whose name derives from applied mathematics and refers to the problem of supplying and distributing products to a network of customers, was launched over a year ago and is in the patenting phase. The objective of the project is to reduce the routes of the ladle transfer lines carts, the movement of which has always been a critical element of the systems. This is even more true for our foundry department, which has no less than 7 melting furnaces for the production of liquid aluminium and 31 die-casting machines, with a variable tonnage of from 500 to 2,700 tons/cm2.

MAKING THE SYSTEMS SAFER AND HAVING FURNACES THAT ENSURE OPTIMUM QUANTITIES AND DENSITY OF MELTED METAL IS THE CHALLENGE TACKLED AND WON BY THE MILKRUN PROJECT

A challenge won thanks to a complex sensor system applied to all the furnaces and an intricate communication network between the production units and the central data processing system.

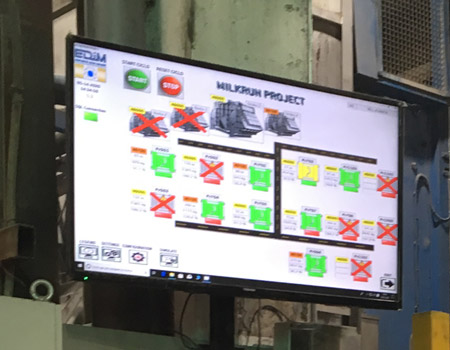

The advantage of this system is that it enables the correct distribution of the material at the right time, that is, only when the quantity of metal is sufficient to fill an entire ladle, so avoiding inefficient trips and superfluous feeding. The safety aspect also benefits from this action, as the movements of the transported melted metal are notably reduced. Additionally, each cart is fitted with a tablet, while a large monitor illustrates the sequence processed by the complex algorithm, benefiting the operators, by indicating when to attach them, which furnaces to fill and which alloy they need to be supplied with.

The design, presented at the Congress of the NADCA (North American Die Casting Association) in Cleveland, met with great interest, both from the technical director of the North American Die Casters’ Association and the large manufacturing companies in the sector: Mercury Marine, RCM and Pace Industries, and Japanese companies Ahresty and Ryobi, groups with plants all over the world. This recognition from Ohio was further confirmation of the great technical vitality and innovative ability that our company, the only foundry in the Bosch Group, expresses in the aluminium foundry process.